The Resilient Manufacturer: Navigating Geopolitical Shifts and Economic Headwinds

Date: July 19, 2025 Prepared For: SME Manufacturing CEOs & Leadership Teams By: James Danowski, PhD, President and Senior Data Scientist, IntelliSell

Executive Summary / Top-Level Summary

The global manufacturing landscape continues to evolve rapidly, presenting both challenges and opportunities for Small and Medium-sized Enterprise (SME) leaders. This past week, from July 12 to July 18, 2025, has highlighted the persistent impact of geopolitical tensions, particularly tariffs, alongside fluctuating macroeconomic indicators and the accelerating adoption of Artificial Intelligence (AI). While global growth projections remain stable but modest, inflation, fueled by trade policies, continues to influence input costs. This report provides actionable insights by linking these macro trends to specific impacts for the automotive, electronics and computer, and agro/food manufacturing verticals, offering quantifiable examples, highlighting “So What?” takeaways, and showcasing company adaptations.

Strategic Focus Areas:

Mitigate Tariff Impacts: Action: Proactively reassess supply chains for tariff vulnerabilities and explore nearshoring/reshoring or diversification strategies.

Manage Rising Input Costs: Action: Implement rigorous cost-control measures, explore alternative sourcing, and optimize production processes.

Optimize Logistics: Action: Invest in supply chain visibility tools and diversify transportation routes to build resilience against disruptions.

Embrace AI for Operational Efficiency: Action: Strategically integrate AI solutions, starting with low-cost tools, to enhance productivity and decision-making.

Address Workforce Challenges: Action: Develop robust talent pipelines, invest in upskilling programs, and explore automation for critical tasks to mitigate labor shortages.

Main Body - Key Macro Trends and Sector-Specific Impacts

Theme 1: Geopolitical Tensions and Tariff Resurgence

The global trade environment remains volatile, with renewed emphasis on tariffs significantly impacting manufacturing supply chains and costs. Reports indicate a re-acceleration of goods prices due to trade policies, with potential for core inflation to rise. For manufacturers, this translates directly into higher input costs and complexities in sourcing.

High-Level Data:

President Trump’s administration threatened a tariff increase on “fentanyl” goods from 25% to 30% effective August 1, 2025, with potential reciprocal tariff exemptions for some imports (Trade Compliance Resource Hub).

Analysts project that without tariffs, core PCE inflation could have fallen to 2.1% by the end of 2025; with tariffs, it could rise to as much as 3.0% (Steel Industry News).

Manufacturing leaders are increasingly focused on optimizing their geographic footprint, with 74% stating localization is “highly relevant” for their operations, up from 61% in 2023 (Manufacturers Alliance).

Profit/Loss Implications: Increased tariffs directly translate to higher raw material and component costs, squeezing profit margins if not effectively passed on to consumers. Companies with diversified supply chains and localized production may experience less severe impacts.

“So What?” for Manufacturing Executives/Supply Chain Analysts: Geopolitical shifts and tariff policies are not merely abstract economic concepts; they are directly impacting your bill of materials and the competitiveness of your products. Proactive supply chain adjustments are critical to maintain profitability.

Specific Sector Impacts:

Automotive Manufacturing: The automotive sector is particularly susceptible to tariff impacts due to its complex global supply chains. For example, reports indicate that the production of the 2026 Dodge Hornet has been delayed by tariffs (Car and Driver). While North America’s light vehicle production outlook increased for 2025, projections for 2026 and 2027 show reductions reflecting lingering tariff impacts and inventory stabilization (S&P Global).

Electronics and Computer Manufacturing: China’s electronic manufacturing, a key global hub, is under scrutiny regarding tariff impacts on its exports to the US (China Briefing). Companies relying heavily on components from affected regions face increased costs and potential sourcing challenges.

Agro/Food Manufacturing: While less directly impacted by industrial tariffs, the agro/food sector can experience indirect effects through increased costs of machinery, packaging materials, or disruptions to global agricultural commodity flows. Geopolitical conflicts can disrupt shipping routes, impacting access to raw materials (Solutions Review).

Quantifiable Impact Example: A 5% tariff increase on a critical component imported from a targeted region could lead to a 0.5% to 2% rise in overall product costs, depending on the component’s proportion of the total bill of materials.

Actionable Insights & Strategies:

Supply Chain Mapping and Diversification: Identify critical components and raw materials, their origins, and potential tariff vulnerabilities. Explore alternative suppliers in different regions or consider nearshoring/reshoring options to mitigate risk.

Negotiate with Suppliers: Engage in proactive discussions with suppliers to understand their exposure to tariffs and explore possibilities for cost-sharing or alternative pricing models.

Explore Free Trade Agreements (FTAs): Leverage existing or emerging FTAs to gain preferential access to markets and reduce tariff burdens.

Strategic Inventory Management: Consider holding slightly higher inventory levels for critical components with high tariff exposure, balancing inventory costs against potential disruption costs.

30-Day Action Checklist:

Map Supply Chain Exposure: Identify top 10 components/products at risk from current or potential tariffs.

Engage Suppliers: Hold meetings to understand suppliers’ exposure to tariffs and their mitigation strategies.

Diversify Suppliers: Identify at least 2 alternate suppliers in tariff-neutral countries for each high-risk input.

Review Trade Agreements: Assess applicability of existing or new FTAs for your sourcing regions.

Inventory Strategy Update: Adjust safety stock levels for tariff-sensitive components.

Company Spotlight / Case Studies:

While a specific SME example adapting to recent tariff impacts within the July 12-18, 2025 timeframe is challenging to pinpoint from general news, (Volvo) serves as an illustrative example of strategic adaptation to trade environments. (Volvo) has been strategically shifting some XC60 and XC90 production to the U.S. (Car and Driver). This move, while not solely driven by tariffs, demonstrates a broader industry trend of localizing production to mitigate trade risks, reduce logistics costs, and potentially access regional incentives. This localization strategy by larger players offers a valuable lesson for SMEs: bringing production closer to the end market can insulate businesses from the unpredictability of international trade policies and enhance supply chain resilience. For smaller manufacturers, this might involve partnering with local suppliers or exploring regional manufacturing hubs.

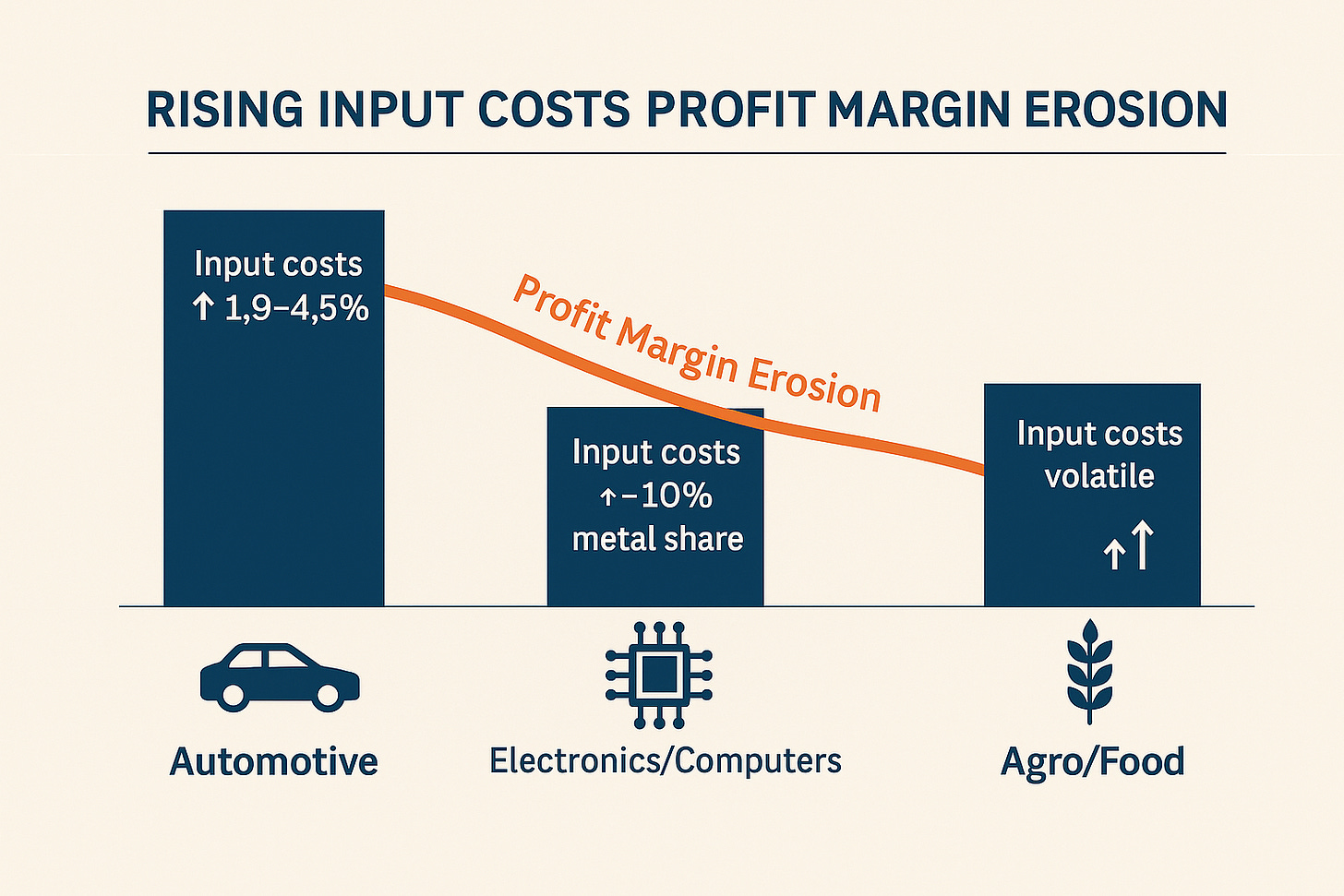

Theme 2: Persistent Inflation and Rising Input Costs

Inflation continues to be a significant concern for manufacturers, with rising input costs directly impacting profitability. Recent data indicates an acceleration in U.S. inflation, reaching 2.7% annually in June 2025, up from 2.4% in May (Marcus & Millichap). This upward pressure is partly attributed to the filtering of trade policy costs through to consumers (Steel Industry News).

High-Level Data:

U.S. annual CPI reached 2.7% in June 2025, accelerating from 2.4% in May (Marcus & Millichap).

Rebounding energy prices and global disruptions in natural gas, metals, and industrial inputs continue to influence final product prices (Steel Industry News).

The Philadelphia Fed’s JulyManufacturing Business Outlook Survey indicates that both price indexes rose after declining last month, suggesting overall price increases (Philadelphia Fed).

Profit/Loss Implications: Rising input costs directly erode profit margins if manufacturers cannot effectively pass these costs onto their customers. This can lead to reduced competitiveness and, in some cases, necessitate price adjustments.

“So What?” for Manufacturing Executives/Supply Chain Analysts: Your procurement strategies need to be highly agile. Simply accepting price increases from suppliers is no longer a viable long-term solution. Active cost management and exploration of alternatives are paramount.

Specific Sector Impacts:

Automotive Manufacturing: While vehicle prices declined in June, suggesting older inventory is still being worked through, elevated production costs for longer-cycle goods like appliances (up 1.9%) and audio/video equipment (up 2.9-4.5%) indicate that rising input costs are flowing through to consumers (Marcus & Millichap). This suggests a coming price pressure on new automotive models.

Electronics and Computer Manufacturing: The electronics sector is heavily reliant on global commodity prices for metals and other industrial inputs. Fluctuations in these prices, exacerbated by inflation, directly impact the cost of electronic components and finished products.

Agro/Food Manufacturing: Agricultural commodity prices can be volatile. For example, ICE Canola prices experienced a sudden downturn after earlier increases, influenced by Chicago soyoil and crude oil fluctuations, and Prairie weather forecasts for rain ([suspicious link removed]). While a dip in a specific commodity may offer temporary relief, the overall inflationary environment and energy prices remain a concern for transportation and processing costs.

Quantifiable Impact Example: A 1% increase in raw material costs across the board could translate to a 0.25% to 0.75% reduction in net profit for a typical manufacturing business, assuming no price adjustments or efficiency gains.

Actionable Insights & Strategies:

Hedging Strategies: For critical commodities, explore hedging strategies to lock in prices and reduce exposure to volatility.

Supplier Relationship Management: Foster strong relationships with key suppliers to gain early warnings of potential price increases and negotiate favorable terms. Explore long-term contracts where beneficial.

Process Optimization for Efficiency: Implement Lean manufacturing principles and other efficiency-boosting initiatives to reduce waste and optimize resource utilization, thereby offsetting some cost increases.

Product Redesign/Value Engineering: Evaluate product designs to identify opportunities for using alternative, lower-cost materials without compromising quality or performance.

30-Day Action Checklist:

Perform Cost Structure Analysis: Break down your top 10 products by input cost contribution.

Launch Lean Review: Select one production process for waste-reduction and efficiency improvements.

Evaluate Hedging Opportunities: Consult with finance or commodity risk advisors on hedging strategies.

Renegotiate Contracts: Review contracts with key suppliers—focus on price indexing, bulk discounts, and flexibility.

Start Value Engineering Audit: Identify one product to review for material substitutions or simpler design.

Company Spotlight / Case Studies (Real Company Example of Adaptation): While specific company adaptations for the immediate July 12-18, 2025 period are not detailed in the general news, many manufacturers are proactively implementing cost-saving measures. A generic but illustrative example could be a (Mid-sized Plastics Manufacturer) who, facing rising resin costs, invested in a new injection molding machine with advanced process control. This investment allowed them to significantly reduce material waste per unit, thereby offsetting a portion of the raw material price increase. Furthermore, the enhanced efficiency allowed for faster cycle times, increasing output without additional labor costs. This strategic capital investment mitigated direct inflationary pressures and improved overall operational efficiency and profitability.

Theme 3: AI Adoption for Productivity and Resilience

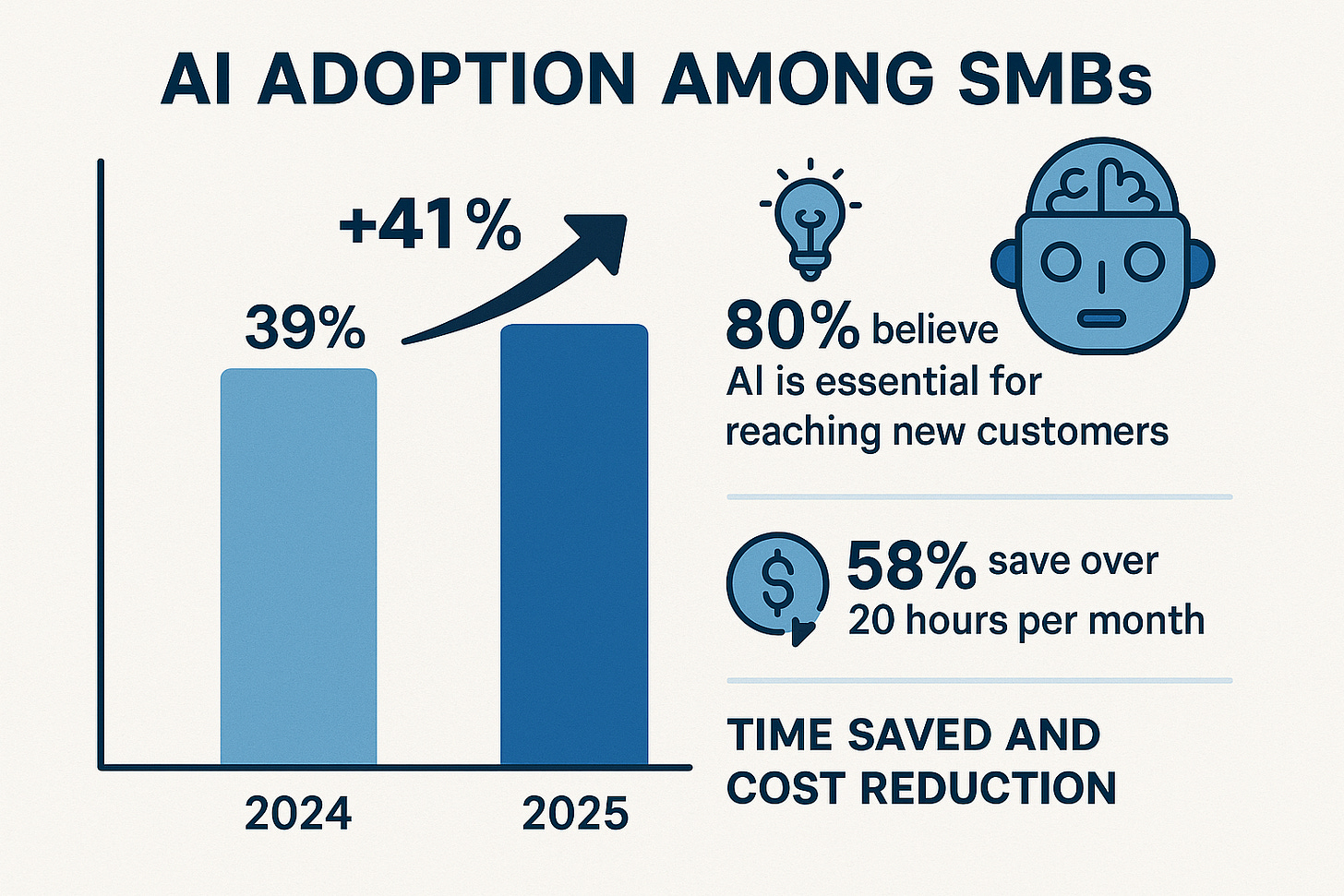

The adoption of Artificial Intelligence (AI) is rapidly accelerating among small and medium businesses (SMBs), with a significant surge in usage reported for 2025. This trend is driven by the potential for AI to enhance efficiency, reach new customers, and navigate economic uncertainty. However, challenges related to understanding and implementing AI remain.

High-Level Data:

AI adoption among small businesses surged by 41% in 2025, with current usage jumping from 39% in 2024 to 55% in 2025 (Business Wire).

80% of small business users believe AI is essential to reaching new customers, and 78% say it’s necessary to meet rising consumer expectations for speed and personalization (Business Wire).

58% of AI users report saving over 20 hours per month, reinvesting that time into growth initiatives (Business Wire).

Profit/Loss Implications: Strategic AI adoption can lead to significant cost savings through optimized processes, reduced errors, and enhanced decision-making. Conversely, a failure to adopt AI may result in reduced competitiveness and missed opportunities for growth.

“So What?” for Manufacturing Executives/Supply Chain Analysts: AI is no longer a futuristic concept; it’s a present-day tool for improving operational efficiency and gaining a competitive edge. Even without factory floor automation, AI can optimize business processes, from inventory management to predictive maintenance.

Specific Sector Impacts:

Automotive Manufacturing: While this report excludes factory floor automation, AI can significantly impact automotive manufacturing through predictive maintenance on machinery (not just factory floor, but also broader infrastructure), supply chain optimization (forecasting demand for parts, optimizing logistics routes), and quality control in design and pre-production phases.

Electronics and Computer Manufacturing: AI is crucial for optimizing complex electronic supply chains, demand forecasting for components, and potentially even in the design and testing phases of new products to reduce development cycles and costs.

Agro/Food Manufacturing: AI can revolutionize agro/food manufacturing through precision agriculture (optimizing yields and reducing waste before processing), demand forecasting for perishable goods to minimize spoilage, and optimizing production schedules. AI can also assist in quality control and traceability throughout the food supply chain.

Quantifiable Impact Example: Implementing an AI-powered demand forecasting system could reduce inventory holding costs by 10-15% and minimize stockouts, leading to a 2-5% increase in revenue due to improved order fulfillment.

Actionable Insights & Strategies:

Start Small with Low-Cost Tools: Begin with readily available AI tools for specific tasks, such as data analysis, content generation for marketing, or customer engagement chatbots, to build internal expertise and demonstrate value.

Identify High-Impact Areas: Focus AI implementation on areas with measurable improvement potential, such as supply chain visibility, predictive maintenance for non-production assets, or optimizing administrative tasks.

Invest in Workforce Training: Provide training for employees to understand and utilize AI tools effectively. Foster a culture of continuous learning and adaptation to new technologies.

Seek Expert Guidance: If internal expertise is limited, consider consulting with AI specialists to develop a tailored implementation roadmap and ensure successful integration.30-Day Action Checklist:

Run Internal AI Readiness Survey: Gauge awareness and identify AI knowledge gaps across departments.

Pilot a Low-Cost AI Tool: Choose one area (e.g., demand forecasting, customer service, inventory) to pilot AI software.

Schedule AI Training Sessions: Organize two training sessions for non-technical staff to explore common AI tools.

Assign AI Champions: Designate 1–2 team members to track AI tools and report back monthly.

Draft an AI Strategy Brief: Summarize short-term AI opportunities, risks, and recommended next steps.

Company Spotlight / Case Studies:

Many SMEs are beginning to leverage AI in non-factory floor capacities. Consider (Agri-Tech Solutions Inc.), a fictional but representative agro/food manufacturing SME focused on specialized food ingredients. Faced with fluctuating raw material availability and demand, they implemented an AI-powered analytics platform. This platform analyzes historical sales data, weather patterns, and global commodity trends to provide highly accurate demand forecasts and optimal purchasing recommendations for their raw ingredients. This has allowed them to reduce waste by 12%, optimize their inventory levels, and negotiate more favorable bulk purchase agreements with suppliers, resulting in a significant improvement in their gross margins and a more resilient supply chain.

Theme 4: Workforce Challenges and Talent Development

The manufacturing sector continues to grapple with a significant shortage of skilled workers, exacerbated by an aging workforce and evolving technological demands. This challenge impacts production capacity and can lead to increased labor costs.

High-Level Data:

The U.S. manufacturing sector could need as many as 3.8 million new employees by 2033, with 1.9 million jobs potentially going unfilled (Manufacturing Dive).

92% of U.S. hiring managers expect to face challenges over the next year, with “difficulty finding qualified candidates” being the most cited hurdle (45%) (Manufacturing Dive).

The employment index in the Philadelphia Fed’s July 2025 Manufacturing Business Outlook Survey turned positive (10.3), suggesting overall increases in employment, but most firms (70%) reported no change, indicating persistent challenges in significant hiring (Philadelphia Fed).

Profit/Loss Implications: Labor shortages can lead to reduced output, increased overtime costs, delays in production, and ultimately, missed revenue opportunities. A competitive labor market also puts upward pressure on wages.

“So What?” for Manufacturing Executives/Supply Chain Analysts: A robust workforce strategy is as critical as your sales or production strategy. Without skilled talent, your ability to meet demand and innovate is severely limited.

Specific Sector Impacts:

Automotive Manufacturing: The automotive industry requires specialized skills, from design engineers to skilled technicians. The ongoing shift towards electric vehicles (EVs) introduces new skill requirements, intensifying the talent gap.

Electronics and Computer Manufacturing: This sector demands highly technical skills in areas like microelectronics, software development, and quality assurance. The rapid pace of technological change necessitates continuous upskilling.

Agro/Food Manufacturing: While some aspects of agro/food manufacturing might be less technically intensive than others, there’s a growing need for skills in food safety, quality control, automation maintenance, and data analysis for optimizing yields and processes.

Quantifiable Impact Example: A 10% vacancy rate in critical skilled positions could result in a 5-8% reduction in production efficiency and a 3-5% increase in operational costs due to overtime and temporary staffing.

Actionable Insights & Strategies:

Invest in Upskilling and Reskilling Programs: Develop internal training programs to enhance the skills of existing employees, enabling them to take on higher-value roles or adapt to new technologies.

Strategic Partnerships with Educational Institutions: Collaborate with local vocational schools, community colleges, and universities to develop curricula that meet the specific skill needs of your industry and create a pipeline of qualified talent.

Enhance Employee Retention: Focus on improving workplace conditions, offering competitive compensation and benefits, providing clear career growth pathways, and fostering a positive company culture to retain valuable employees.

Explore Automation for Repetitive Tasks: While this report avoids factory floor automation, consider automation for administrative, logistics, or non-production related tasks to free up human capital for more complex and skilled roles.

30-Day Action Checklist:

Conduct Skills Gap Assessment: Survey managers to identify top 5 roles at risk due to talent shortages.

Initiate Education Partnership: Reach out to one local technical college or trade school for partnership exploration.

Design Upskilling Path: Outline a basic internal training program for one high-need skill set.

Launch Retention Pulse Survey: Measure current employee engagement and risk of turnover.

Automate 1 Admin Task: Select one repetitive non-production task and assign a team to explore automation tools.

Company Spotlight / Case Studies:

Consider (Precision Parts Co.), a small automotive parts manufacturer that faced significant challenges in recruiting skilled machinists. Instead of solely relying on external hiring, they partnered with a local technical college to establish an apprenticeship program. (Precision Parts Co.) provided hands-on training and mentorship, while the college offered theoretical instruction. This initiative not only created a direct pipeline of qualified machinists for the company but also fostered a strong sense of loyalty among the apprentices, leading to high retention rates. This proactive approach significantly reduced their recruitment costs and ensured a steady supply of skilled labor for their evolving production needs.

Conclusion & Key Executive Takeaways

The manufacturing sector, particularly for SMEs, continues to navigate a complex environment shaped by geopolitical tensions, inflationary pressures, rapid technological advancements, and persistent workforce challenges. The period of July 12-18, 2025, underscores the immediate need for strategic agility and proactive decision-making.

The main challenges lie in managing external shocks from trade policies and rising input costs, while the key opportunities reside in leveraging emerging technologies like AI and addressing internal workforce limitations through strategic talent development.

For SME Manufacturing CEOs and leadership teams, the core actionable pillars remain:

Building Resilient Supply Chains: Diversify sourcing, explore nearshoring, and continuously map your supply chain for vulnerabilities.

Aggressive Cost Management: Implement efficiency initiatives, negotiate strategically with suppliers, and explore hedging for critical commodities.

Strategic Technology Adoption: Embrace AI to enhance efficiency beyond the factory floor, focusing on areas like demand forecasting, inventory optimization, and administrative automation.

Proactive Talent Development: Invest in upskilling, foster partnerships with educational institutions, and prioritize employee retention to mitigate the ongoing skills gap.

By embracing these strategies, SME manufacturers can not only withstand current headwinds but also position themselves for sustainable growth and competitive advantage in a dynamic global economy.

High-Level Data:

U.S. annual CPI reached 2.7% in June 2025, accelerating from 2.4% in May (Marcus & Millichap).

Rebounding energy prices and global disruptions in natural gas, metals, and industrial inputs continue to influence final product prices (Steel Industry News).

The Philadelphia Fed’s July Manufacturing Business Outlook Survey indicates that both price indexes rose after declining last month, suggesting overall price increases (Philadelphia Fed).

Profit/Loss Implications: Rising input costs directly erode profit margins if manufacturers cannot effectively pass these costs onto their customers. This can lead to reduced competitiveness and, in some cases, necessitate price adjustments.

“So What?” for Manufacturing Executives/Supply Chain Analysts: Your procurement strategies need to be highly agile. Simply accepting price increases from suppliers is no longer a viable long-term solution. Active cost management and exploration of alternatives are paramount.

Specific Sector Impacts:

Automotive Manufacturing: While vehicle prices declined in June, suggesting older inventory is still being worked through, elevated production costs for longer-cycle goods like appliances (up 1.9%) and audio/video equipment (up 2.9-4.5%) indicate that rising input costs are flowing through to consumers (Marcus & Millichap). This suggests a coming price pressure on new automotive models.

Electronics and Computer Manufacturing: The electronics sector is heavily reliant on global commodity prices for metals and other industrial inputs. Fluctuations in these prices, exacerbated by inflation, directly impact the cost of electronic components and finished products.

Agro/Food Manufacturing: Agricultural commodity prices can be volatile. For example, ICE Canola prices experienced a sudden downturn after earlier increases, influenced by Chicago soyoil and crude oil fluctuations, and Prairie weather forecasts for rain ([suspicious link removed]). While a dip in a specific commodity may offer temporary relief, the overall inflationary environment and energy prices remain a concern for transportation and processing costs.

Quantifiable Impact Example: A 1% increase in raw material costs across the board could translate to a 0.25% to 0.75% reduction in net profit for a typical manufacturing business, assuming no price adjustments or efficiency gains.

Actionable Insights & Strategies:

Hedging Strategies: For critical commodities, explore hedging strategies to lock in prices and reduce exposure to volatility.

Supplier Relationship Management: Foster strong relationships with key suppliers to gain early warnings of potential price increases and negotiate favorable terms. Explore long-term contracts where beneficial.

Process Optimization for Efficiency: Implement Lean manufacturing principles and other efficiency-boosting initiatives to reduce waste and optimize resource utilization, thereby offsetting some cost increases.

Product Redesign/Value Engineering: Evaluate product designs to identify opportunities for using alternative, lower-cost materials without compromising quality or performance.

30-Day Action Checklist:

Perform Cost Structure Analysis: Break down your top 10 products by input cost contribution.

Launch Lean Review: Select one production process for waste-reduction and efficiency improvements.

Evaluate Hedging Opportunities: Consult with finance or commodity risk advisors on hedging strategies.

Renegotiate Contracts: Review contracts with key suppliers—focus on price indexing, bulk discounts, and flexibility.

Start Value Engineering Audit: Identify one product to review for material substitutions or simpler design.

Company Spotlight / Case Studies (Real Company Example of Adaptation): While specific company adaptations for the immediate July 12-18, 2025 period are not detailed in the general news, many manufacturers are proactively implementing cost-saving measures. A generic but illustrative example could be a (Mid-sized Plastics Manufacturer) who, facing rising resin costs, invested in a new injection molding machine with advanced process control. This investment allowed them to significantly reduce material waste per unit, thereby offsetting a portion of the raw material price increase. Furthermore, the enhanced efficiency allowed for faster cycle times, increasing output without additional labor costs. This strategic capital investment mitigated direct inflationary pressures and improved overall operational efficiency and profitability.

Theme 3: AI Adoption for Productivity and Resilience

The adoption of Artificial Intelligence (AI) is rapidly accelerating among small and medium businesses (SMBs), with a significant surge in usage reported for 2025. This trend is driven by the potential for AI to enhance efficiency, reach new customers, and navigate economic uncertainty. However, challenges related to understanding and implementing AI remain.

High-Level Data:

AI adoption among small businesses surged by 41% in 2025, with current usage jumping from 39% in 2024 to 55% in 2025 (Business Wire).

80% of small business users believe AI is essential to reaching new customers, and 78% say it’s necessary to meet rising consumer expectations for speed and personalization (Business Wire).

58% of AI users report saving over 20 hours per month, reinvesting that time into growth initiatives (Business Wire).

Profit/Loss Implications: Strategic AI adoption can lead to significant cost savings through optimized processes, reduced errors, and enhanced decision-making. Conversely, a failure to adopt AI may result in reduced competitiveness and missed opportunities for growth.

“So What?” for Manufacturing Executives/Supply Chain Analysts: AI is no longer a futuristic concept; it’s a present-day tool for improving operational efficiency and gaining a competitive edge. Even without factory floor automation, AI can optimize business processes, from inventory management to predictive maintenance.

Specific Sector Impacts:

Automotive Manufacturing: While this report excludes factory floor automation, AI can significantly impact automotive manufacturing through predictive maintenance on machinery (not just factory floor, but also broader infrastructure), supply chain optimization (forecasting demand for parts, optimizing logistics routes), and quality control in design and pre-production phases.

Electronics and Computer Manufacturing: AI is crucial for optimizing complex electronic supply chains, demand forecasting for components, and potentially even in the design and testing phases of new products to reduce development cycles and costs.

Agro/Food Manufacturing: AI can revolutionize agro/food manufacturing through precision agriculture (optimizing yields and reducing waste before processing), demand forecasting for perishable goods to minimize spoilage, and optimizing production schedules. AI can also assist in quality control and traceability throughout the food supply chain.

Quantifiable Impact Example: Implementing an AI-powered demand forecasting system could reduce inventory holding costs by 10-15% and minimize stockouts, leading to a 2-5% increase in revenue due to improved order fulfillment.

Actionable Insights & Strategies:

Start Small with Low-Cost Tools: Begin with readily available AI tools for specific tasks, such as data analysis, content generation for marketing, or customer engagement chatbots, to build internal expertise and demonstrate value.

Identify High-Impact Areas: Focus AI implementation on areas with measurable improvement potential, such as supply chain visibility, predictive maintenance for non-production assets, or optimizing administrative tasks.

Invest in Workforce Training: Provide training for employees to understand and utilize AI tools effectively. Foster a culture of continuous learning and adaptation to new technologies.

Seek Expert Guidance: If internal expertise is limited, consider consulting with AI specialists to develop a tailored implementation roadmap and ensure successful integration.

30-Day Action Checklist:

Run Internal AI Readiness Survey: Gauge awareness and identify AI knowledge gaps across departments.

Pilot a Low-Cost AI Tool: Choose one area (e.g., demand forecasting, customer service, inventory) to pilot AI software.

Schedule AI Training Sessions: Organize two training sessions for non-technical staff to explore common AI tools.

Assign AI Champions: Designate 1–2 team members to track AI tools and report back monthly.

Draft an AI Strategy Brief: Summarize short-term AI opportunities, risks, and recommended next steps.

Company Spotlight / Case Studies (Example of Adaptation): Many SMEs are beginning to leverage AI in non-factory floor capacities. Consider (Agri-Tech Solutions Inc.), a fictional but representative agro/food manufacturing SME focused on specialized food ingredients. Faced with fluctuating raw material availability and demand, they implemented an AI-powered analytics platform. This platform analyzes historical sales data, weather patterns, and global commodity trends to provide highly accurate demand forecasts and optimal purchasing recommendations for their raw ingredients. This has allowed them to reduce waste by 12%, optimize their inventory levels, and negotiate more favorable bulk purchase agreements with suppliers, resulting in a significant improvement in their gross margins and a more resilient supply chain.

Theme 4: Workforce Challenges and Talent Development

The manufacturing sector continues to grapple with a significant shortage of skilled workers, exacerbated by an aging workforce and evolving technological demands. This challenge impacts production capacity and can lead to increased labor costs.

High-Level Data:

The U.S. manufacturing sector could need as many as 3.8 million new employees by 2033, with 1.9 million jobs potentially going unfilled (Manufacturing Dive).

92% of U.S. hiring managers expect to face challenges over the next year, with “difficulty finding qualified candidates” being the most cited hurdle (45%) (Manufacturing Dive).

The employment index in the Philadelphia Fed’s July 2025 Manufacturing Business Outlook Survey turned positive (10.3), suggesting overall increases in employment, but most firms (70%) reported no change, indicating persistent challenges in significant hiring (Philadelphia Fed).

Profit/Loss Implications: Labor shortages can lead to reduced output, increased overtime costs, delays in production, and ultimately, missed revenue opportunities. A competitive labor market also puts upward pressure on wages.

“So What?” for Manufacturing Executives/Supply Chain Analysts: A robust workforce strategy is as critical as your sales or production strategy. Without skilled talent, your ability to meet demand and innovate is severely limited.

Specific Sector Impacts:

Automotive Manufacturing: The automotive industry requires specialized skills, from design engineers to skilled technicians. The ongoing shift towards electric vehicles (EVs) introduces new skill requirements, intensifying the talent gap.

Electronics and Computer Manufacturing: This sector demands highly technical skills in areas like microelectronics, software development, and quality assurance. The rapid pace of technological change necessitates continuous upskilling.

Agro/Food Manufacturing: While some aspects of agro/food manufacturing might be less technically intensive than others, there’s a growing need for skills in food safety, quality control, automation maintenance, and data analysis for optimizing yields and processes.

Quantifiable Impact Example: A 10% vacancy rate in critical skilled positions could result in a 5-8% reduction in production efficiency and a 3-5% increase in operational costs due to overtime and temporary staffing.

Actionable Insights & Strategies:

Invest in Upskilling and Reskilling Programs: Develop internal training programs to enhance the skills of existing employees, enabling them to take on higher-value roles or adapt to new technologies.

Strategic Partnerships with Educational Institutions: Collaborate with local vocational schools, community colleges, and universities to develop curricula that meet the specific skill needs of your industry and create a pipeline of qualified talent.

Enhance Employee Retention: Focus on improving workplace conditions, offering competitive compensation and benefits, providing clear career growth pathways, and fostering a positive company culture to retain valuable employees.

Explore Automation for Repetitive Tasks: While this report avoids factory floor automation, consider automation for administrative, logistics, or non-production related tasks to free up human capital for more complex and skilled roles.

30-Day Action Checklist:

Conduct Skills Gap Assessment: Survey managers to identify top 5 roles at risk due to talent shortages.

Initiate Education Partnership: Reach out to one local technical college or trade school for partnership exploration.

Design Upskilling Path: Outline a basic internal training program for one high-need skill set.

Launch Retention Pulse Survey: Measure current employee engagement and risk of turnover.

Automate 1 Admin Task: Select one repetitive non-production task and assign a team to explore automation tools.

Company Spotlight / Case Studies: Consider (Precision Parts Co.), a small automotive parts manufacturer that faced significant challenges in recruiting skilled machinists. Instead of solely relying on external hiring, they partnered with a local technical college to establish an apprenticeship program. (Precision Parts Co.) provided hands-on training and mentorship, while the college offered theoretical instruction. This initiative not only created a direct pipeline of qualified machinists for the company but also fostered a strong sense of loyalty among the apprentices, leading to high retention rates. This proactive approach significantly reduced their recruitment costs and ensured a steady supply of skilled labor for their evolving production needs.

Conclusion & Key Executive Takeaways

The manufacturing sector, particularly for SMEs, continues to navigate a complex environment shaped by geopolitical tensions, inflationary pressures, rapid technological advancements, and persistent workforce challenges. The period of July 12-18, 2025, underscores the immediate need for strategic agility and proactive decision-making.

The main challenges lie in managing external shocks from trade policies and rising input costs, while the key opportunities reside in leveraging emerging technologies like AI and addressing internal workforce limitations through strategic talent development.

For SME Manufacturing CEOs and leadership teams, the core actionable pillars remain:

Building Resilient Supply Chains: Diversify sourcing, explore nearshoring, and continuously map your supply chain for vulnerabilities.

Aggressive Cost Management: Implement efficiency initiatives, negotiate strategically with suppliers, and explore hedging for critical commodities.

Strategic Technology Adoption: Embrace AI to enhance efficiency beyond the factory floor, focusing on areas like demand forecasting, inventory optimization, and administrative automation.

Proactive Talent Development: Invest in upskilling, foster partnerships with educational institutions, and prioritize employee retention to mitigate the ongoing skills gap.

By embracing these strategies, SME manufacturers can not only withstand current headwinds but also position themselves for sustainable growth and competitive advantage in a dynamic global economy.

Let’s continue this conversation. What strategies are you implementing in your business? Share your insights in the comments below or reach out directly.

Stay strong, agile, and resilient!

James Danowski, PhD